08 Mar HAIMER EXCLUSIVE CNC PRESETTER, BALANCER, & SHRINK FIT TECHNOLOGY PARTNER OF ROUSH YATES ENGINES

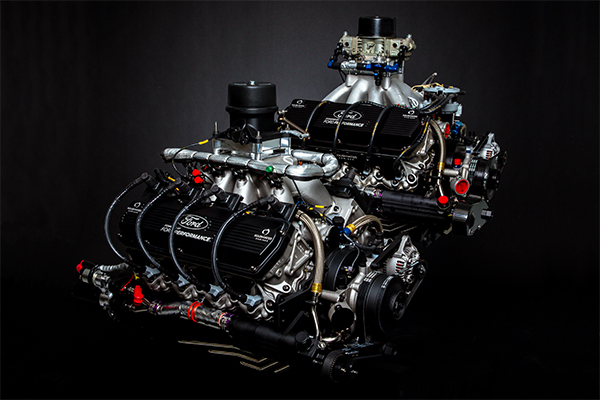

MOORESVILLE, NC – March 8, 2023 – Roush Yates Engines & Haimer USA entered a multi-year partnership agreement to support the critical CNC machining of engine components for Ford’s FR9 NASCAR engine. Roush Yates Engines designs, develops, and builds high performance racing engines in partnership with Ford Performance for NASCAR’s Cup, Xfinty and IMSA’s Michelin Pilot Challenge Series. In order to expedite engineering innovation, 50% of the FR9 engine components are machined internally at Roush Yates Manufacturing Solutions (RYMS).

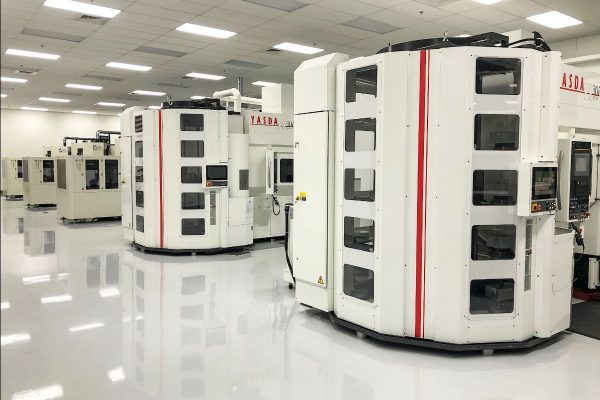

RYMS is an AS 9100 Rev D/ISO 13485 certified contract manufacturer of complex geometry parts for critical applications that require robust process control and post machine surface treatments for motorsports, aerospace, defense, space, and medical industries. Roush Yates Manufacturing Solutions will leverage the innovation and dedication of HAIMER at its 88,000 square foot manufacturing facility located in Mooresville, NC.

“HAIMER is a world class company with premier technology and equipment that will have a significant impact on machining engine components as well as other components for motorsports, aerospace, defense, space, and medical markets,” said Doug Yates, President and CEO of Roush Yates Engines. “As we continue to race for championships and focus on precision machining, HAIMER is the next step to gain that competitive advantage on and off the racetrack.”

Roush Yates Manufacturing Solutions will utilize the Vio Linear Presetter, Power Clamp Eco Air i4.0 Heat Shrink machine, and the TD Comfort with Extended Hood Balancer.

“HAIMER is honored and proud to be working as a partner of Roush Yates Manufacturing Solutions, a leader in the field of motorsports and modern, high-end manufacturing,” said Brendt Holden, President of HAIMER USA. “We feel that our tool room technology will support their production machining to be a consistent winner in the manufacturing industry.”

“The HAIMER technology will allow RYMS leverage its manufacturing knowledge and offer its customers with a greater ability to take on more complex and tighter tolerance components,” said Bryan Gresock, President of Roush Yates Manufacturing Solutions. “Having this capability will help continue our offerings to the manufacturing industry where tolerances and lead times are being reduced. The partnership with HAIMER will help RYMS stay at the forefront of offering the very best solutions for our customers.”

About Roush Yates Engines:

Roush Yates Engines is a leading-edge engine development company based in Mooresville, NC consisting of two state-of-the-art facilities – Roush Yates Engines and Roush Yates Manufacturing Solutions. The company’s core business includes designing, building, and testing purpose-built race engines.

Roush Yates Engines (RYE) in partnership with Ford Performance is the exclusive engine builder of the NASCAR FR9 Ford V8 engine and Ford Mustang 5.2L V8 engine, used in the IMSA Michelin Pilot Challenge series.

Roush Yates Manufacturing Solutions is an AS9100 Rev D/ ISO 13485 high precision machining division of RYE. Our expertise is in the CNC machining of complex geometry parts for critical applications that require robust process control and post machine surface treatments. We provide an array of automated CNC manufacturing on 5 and 4 axis mills. In addition, we offer Multi-axis mill turns, turning, Swiss Turn, and waterjet machining. We also offer post machine surfacing, secondary treatment processes, and sub-assembly services in-house and through a network of validated and approved process suppliers. We produce machined components for the motorsports, aerospace, defense, space, and medical markets.

For more information about RYE, visit www.roushyates.com.

About HAIMER USA:

HAIMER is a family run, medium size company first class German Tool Holder manufacturer located in Igenhausen, Bavaria near Augsburg, Germany. From the basics of face-mill arbors and ER collet chucks, all the way up to High Precision Collet and Shrink Fit Chucks, HAIMER has the tools necessary to satisfy and exceed your machining center needs. HAIMER’s product line includes the most extensive taper and size offerings from any HSK, CAT, BT, SK, PSC and KM tapers to any inch or metric size available.

HAIMER also manufactures its own Balancing Machines, Shrink-Fit Machines, Presetting Machines, 3 Dimensional Edge Finders and Solid Carbide Endmills. HAIMER’s philosophy of “Quality Wins” can be seen at the shop floor level with the use of HAIMER products. Not only will the quality increase, but the cutting tool life and machine tool spindle life will also increase.

HAIMER USA has a 40,000 square foot facility containing a showroom, offices and a full stocking warehouse located in Villa Park, IL, a western suburb of Chicago.

For more information about HAIMER USA, visit www.haimer-usa.com/.