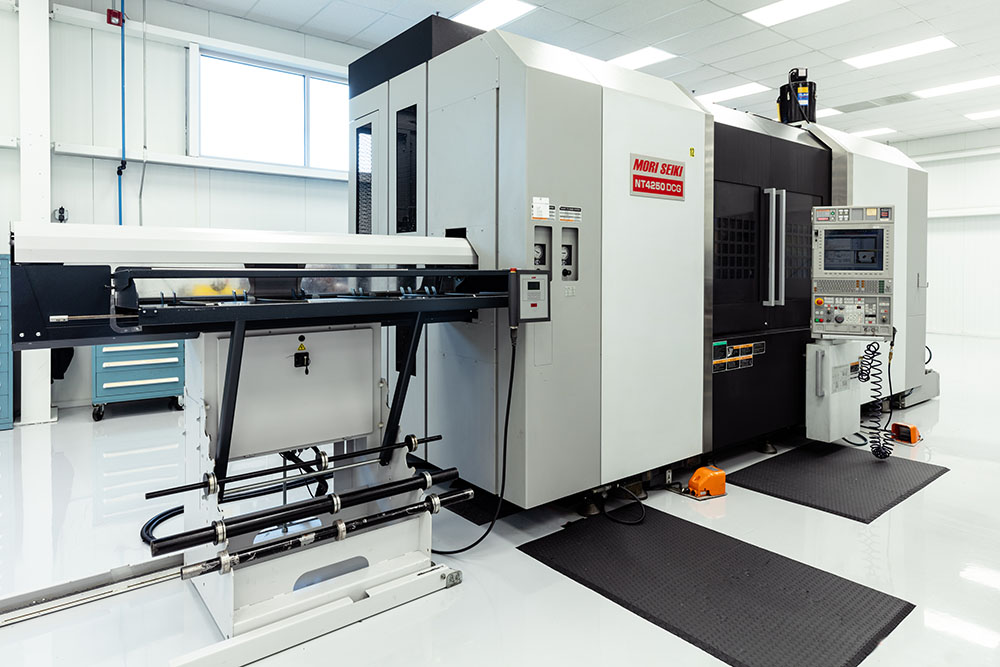

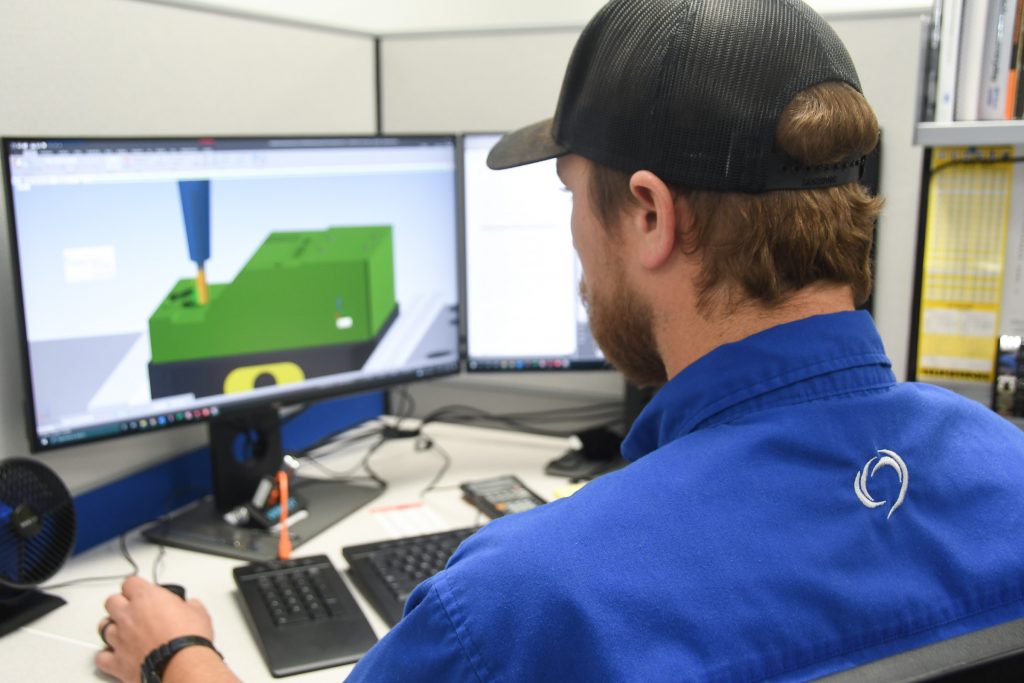

Our expertise is in the CNC machining of complex geometry parts that require precision and robust process control. We provide an array of advance manufacturing processes on 4 and 5 axis mills, automation centers, waterjet, multi-axis mill turn, and Swiss turn machines. In addition, we offer post-machine surface, secondary treatment processes, and subseries through a network of validated suppliers.

What does CNC stand for? Computer Numerical Code

- 88,000 Square Foot Climate-Controlled Facility

- 55,000 Square Foot Climate-Controlled Facility

- State-of-the-Art Machines

- AS 9100 Rev D, ISO 13485 Certified by NSF-ISR

- ITAR Registered

- Over 98 Years of Collective Experience