08 May INSIDE ROUSH YATES MANUFACTURING SOLUTIONS: CUTTING-EDGE CNC LATHE CAPABILITIES

At Roush Yates Manufacturing Solutions, CNC (Computer Numerical Control) lathes have revolutionized the way we machine precise and complex components. These machines have taken traditional lathe operations to new heights, offering unparalleled accuracy, efficiency, and versatility across various industries. Whether we are machining parts for motorsports, aerospace, defense, space, or medical industries, CNC lathes are indispensable tools at our facility.

Lathe Capabilities at Roush Yates Manufacturing Solutions

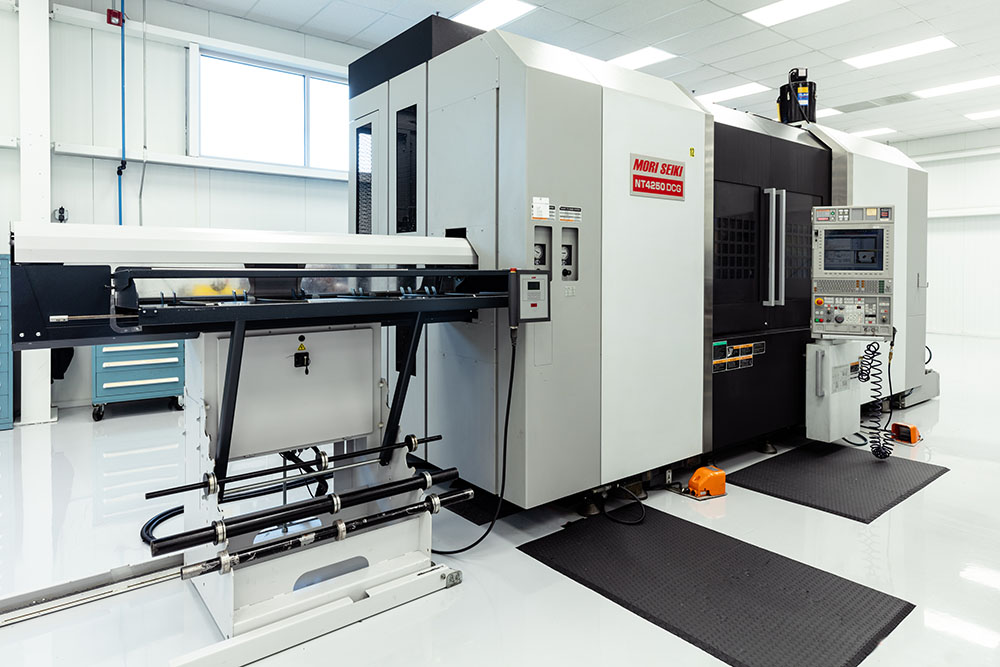

At RYMS, our CNC lathe department features a robust line-up of multi-axis, high-performance turning centers, and mill-turn centers that are equipped to handle a wide variety of part sizes and complexities. Our machines include:

- Live tooling and sub-spindles for performing multiple operations in a single setup.

- Bar feeders and robotic part handling to facilitate high-volume, unattended production runs.

- The ability to machine both soft and hardened materials including aluminum, stainless steel, titanium, Inconel, and more.

- Tight tolerance machining with repeatability and precision ideal for high-demand industries.

We pride ourselves on the ability to produce everything from small precision components to large structural parts with exceptional accuracy and finish. Whether it’s smaller batch sizes to full-scale production, our CNC lathes can adapt to the job.

Advantages of CNC Lathes

- Precision and Accuracy – Our machines deliver tolerances within a few microns, ensuring repeatability for mission-critical parts

- Increased Efficiency – High-speed operations and reduced downtime allow our team to manage multiple machines simultaneously, boosting overall productivity.

- Versatility – Multi-axis capabilities allow for turning, milling, drilling, and tapping all within one setup, improving throughput and accuracy. With the capacity to handle a range of part sizes—from components under 1 inch in diameter to over 36 inches—our lathes can support any level of production complexity.

- Reduced Waste and Cost Savings – CNC automation reduces material waste and human error, lowering overall production costs.

Consistent Quality

Since CNC lathes follow pre-programmed instructions, they ensure that every part produced is consistent. This consistency is crucial for industries that require strict quality standards, such as aerospace and medical device manufacturing. Lathe machining at RYMS is also supported by rigorous quality control measures, including:

- Advanced Metrology Equipment: Coordinate Measuring Machines (CMMs), vision systems, and optical comparators throughout the shop floor to validate parts in real time.

- Certified Standards: AS9100 Rev D and ISO 13485 certifications ensure compliance with industry standards.

- Skilled Workforce: Our experience engineers, programmers, and machinists apply decades of experience to optimize every setup and process.

Applications of CNC Lathes

- Aerospace parts – High-precision engine components and structural elements.

- Motorsports components – Retainers, rocker arms, uprights, shifters, fuel cell top assembly, and customer parts.

- Medical devices – Surgical instruments and robotic equipment components.

- Defense and Space – Rugged, light weight, high-tolerance components for mission-critical systems.

Why Choose RYMS?

Roush Yates Manufacturing Solutions is a leader in precision machining, offering unmatched quality, efficiency, and reliability. Our advanced CNC lathe capabilities, combined with secondary operations such as assembly, testing, chem-film, and paint, allow us to deliver a true end-to-end manufacturing solution.

Click here to learn more about our world-class facility and capabilities.