30 Jan PRECISION MILLING CAPABILITIES AT ROUSH YATES MANUFACTURING SOLUTIONS

Leveraging state-of-the-art technology and a highly skilled team, Roush Yates Manufacturing Solutions (RYMS) specializes in the machining of high-performance, precision-engineered components for the motorsports, aerospace, defense, space, and medical industries. One of the core competencies of RYMS is their world-class milling capabilities.

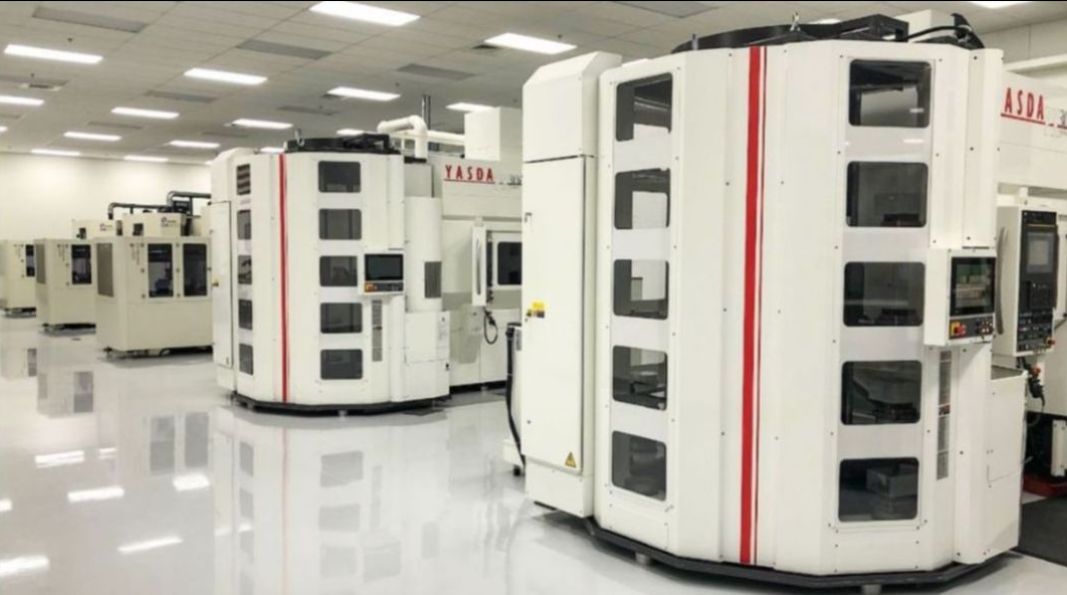

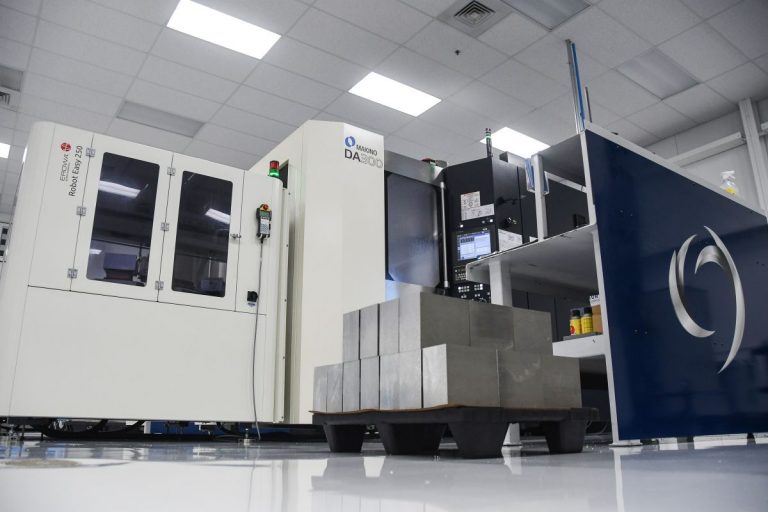

Advanced Milling Machines

At RYMS, the milling department features a wide range of cutting-edge machines designed to handle the most demanding projects. Equipped with multi-axis CNC (Computer Numerical Control) automated machines, RYMS delivers unparalleled precision and efficiency. With 3-axis, 4-axis, and 5-axis milling machines, each is tailored to execute complex geometries, efficiencies, and achieve exceptional surface finishes.

Benefits of Milling Machines Include:

- High-Speed Machining: With advanced spindles reaching high RPMs, RYMS ensures faster cycle times without compromising precision.

- Tight Tolerances: The ability to consistently hold tolerances as tight as +/- 7 microns guarantees components meet customer’s requirements.

- Large Envelope Capabilities: Machines capable of handling both small and large parts cater to diverse project requirements.

- Single Setups: 5-Axis machines allow for single setups to complete parts without multiple stages. This reduces setup time, cycle time, and overall green-to-green time.

- Multiple Pallets: Over 1/3 of the milling machines at RYMS have 10+ pallets, up to 40 pallets. This allows multiple jobs to be set up at any given time and the ability to machine 24 hours / 7 days a week.

Materials Expertise:

RYMS excels in milling a broad spectrum of materials, from lightweight aluminum to high-strength alloys such as hardened stainless, titanium, and Inconel.

Commitment to Quality:

Quality is a cornerstone of operations at RYMS. Milling processes are supported by rigorous rapid response quality control measures, including:

- Advanced Metrology Equipment: Coordinate Measuring Machines (CMMs) stationed throughout the shop floor for real time results, vision systems, and optical comparators ensuring every component meets required specifications.

- Certified Standards: Roush Yates Manufacturing Solutions is AS9100 Rev D / ISO 13485 certified, delivering consistent and reliable results.

- Skilled Workforce: A team of experienced machinists, quality technicians, and engineers bring unparalleled expertise to every project.

Why Choose RYMS for Milling Services?

Roush Yates Manufacturing Solutions offers more than just advanced milling technology; they deliver an end-to-end manufacturing experience defined by innovation, precision, and reliability.

Ready to elevate your manufacturing projects? Click here to learn more about our capabilities.