19 Aug ROUSH YATES MANUFACTURING SOLUTIONS MOVES TO PAPERLESS CNC MACHINING FACILITY WITH PROSHOP

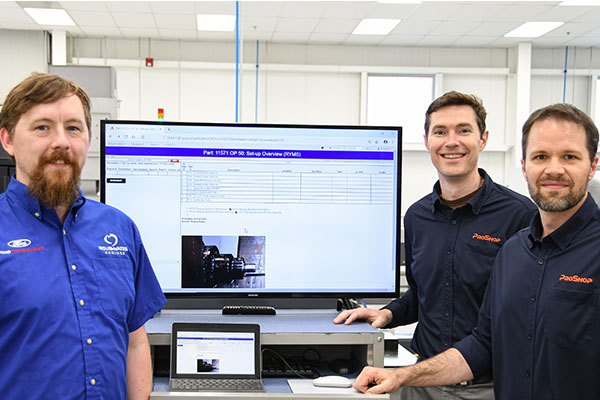

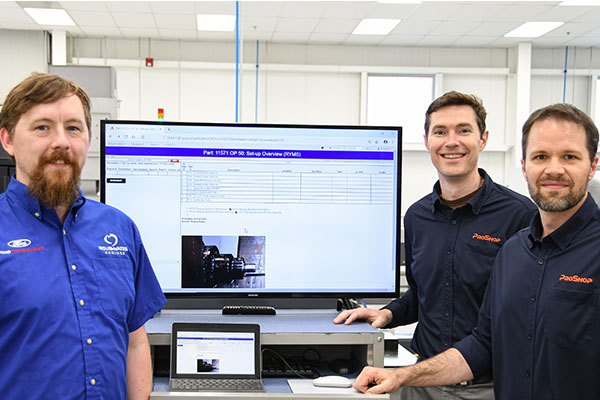

Roush Yates Manufacturing Solutions announced today a new multi-year partnership with ProShop USA Inc.

Established in Bellingham, WA, ProShop’s manufacturing enterprise software is a comprehensive paperless shop management system, engineered to benefit growing manufacturing companies. It’s a system built by a manufacturer for manufacturers, especially with AS9100 certified companies in mind.

“With ProShop we have complete visibility of our products and operations from estimating to shipping, real time inspection reporting to reduce scrap and rework, and intuitive inventory control, so we spend more time cutting chips and less time waiting for tools,” said Malcolm Pruitt, Manufacturing Planner, Roush Yates Manufacturing Solutions. “ProShop provides the reliability that today’s industry demands.”

“As we expanded into an 88,000 sq. ft. world-class facility with 50 CNC machines, it was important that we did things thoughtfully and with clear intention,” commented Mitch Miller, VP of Manufacturing, Roush Yates Manufacturing Solutions. “We knew we needed a tool that could flex and scale as we grew and would be user friendly for our 50 plus employees to use throughout the plant. As we reviewed products and results, it was clear the best choice for our CNC manufacturing facility was ProShop.”

ProShop is playing a vital role at Roush Yates Manufacturing Solutions (RYMS). RYMS is utilizing ProShop’s vast experience and module-built Digital Manufacturing Eco System to help expand and connect our growing facility. The turn-key software brings the tools of ERP, MES, and QMS together to make one complete robust package.

About Proshop:

ProShop is the industry’s only ERP system specifically dedicated to and built in a CNC machine shop. We are fanatical about managing every detail of your machine shop in a paperless and web-based environment, including the ERP functions necessary to run your office, the QMS functions to manage your ISO or AS9100 system, and the MES functions to ensure your shop floor is running at peak efficiency. From managing visual work instructions, drawing revisions, job-routings, cutting tools, FAI and In-process inspection, NCR generation, calibration, machine utilization, job-costing, and much more, it’s all in ProShop and completely interconnected to every corner of your business. Leading shops know that going paperless and digital is the future for all machine shops. We’ve helped more shops go completely paperless than any other provider on the market. We live it and breathe every day, and it’s our passion to help you improve your business.

To learn more about ProShop go to proshoperp.com.